Updated on: 25/03/2020

Image Source: mt.com

Image Source: mt.com

Analytical balance accuracy can only be achieved if the scale operator is consistently alert and careful. Even with alert and careful operators, other factors can influence the analytical balance calibration. In instances where precision is vital, an error of 0.001 grams or even smaller can be quite significant.

Analytical balance errors can arise when the instrument records an inaccurate weight of samples owing to internal and external influences unknown to the operator or because of poor weighing practices.

While errors that are induced externally may be a result of numerous factors, they can be eliminated or reduced easily. In most instances, the causes can be traced to a lapse in precision balance operating procedures that relate to laboratory environment or the sample. To attain analytical precision, it is important to maintain a constant load on the balance beam while subtracting mass on that side of the beam where the sample is added.

Thus, the overall balance is attained using a small spring force as opposed to deducting fixed weights. Consequently, weight is added only as a sufficient adjustment. Ultimately, to attain analytical balance, you need to follow the manufacturer’s instructions, maintain calibration frequency as well as maintenance recommendations.

When to Use Analytical Balances

An analytical balance is often used when it is necessary to know the precise mass of any substance. This can be used for getting the exact measurements to ensure the safety of products or for minimizing by-products. It also enables you to make a controlled resource budget. For instance, the analytical balance may be used to measure the accurate amounts of reagents as well as the amount of product that was produced. Analytical balance can be used for measuring weights ranging from 0.1 mg to 200 g.

The ability to measure such small intervals means that specific steps must be taken before taking the measurements. The balances are different from other scales in the sense that the weighing area is encased to protect it from the external factors. This is designed to minimize the effects of temperature and pressure while taking the measurements. Therefore, it is vital to ensure the door is closed before you begin taking the final measurement. Inaccuracies in measurements may be prevented by placing the balance away from burners, vents as well as other ventilation.

How to Use Analytical Balance

Follow the steps below to operate an analytical balance.

- Use a level indicator to check the balance. Make sure that the bubble is in the center. If it is not, adjust it by twisting the feet.

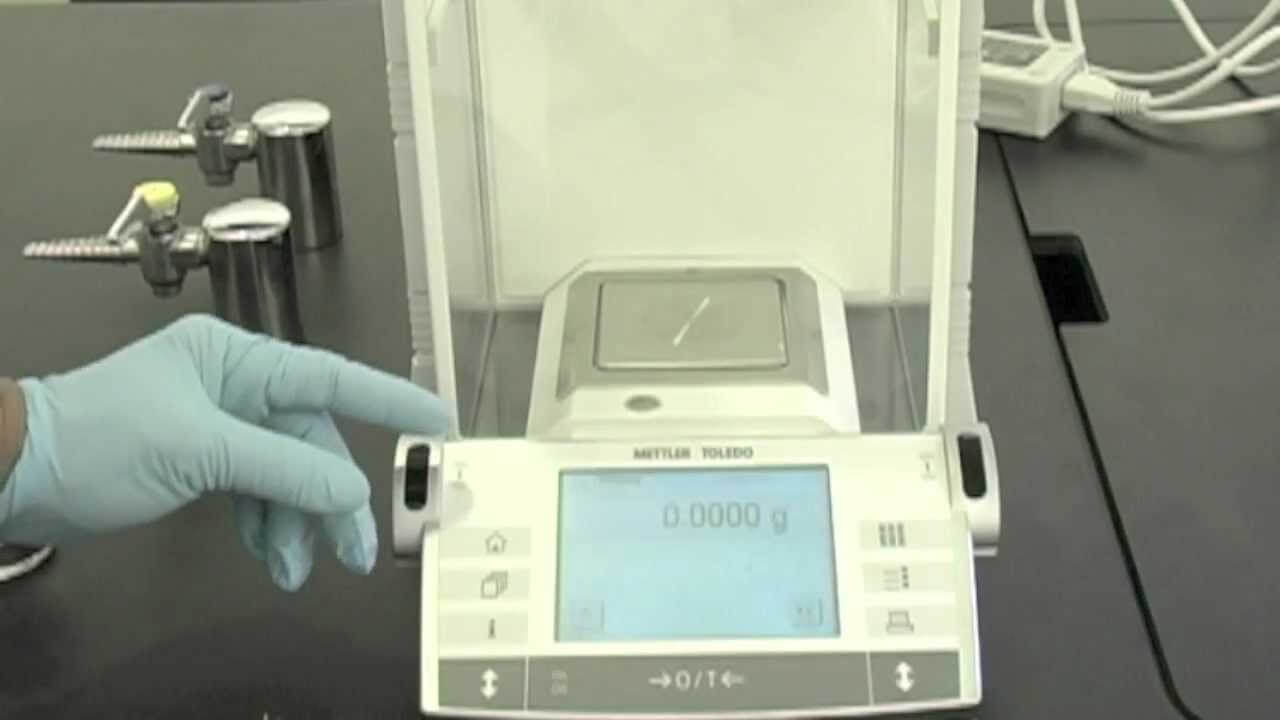

- Turn the balance on. Press the ‘tare’ button and wait for a ‘*’ or a similar symbol to appear on any of the top corners. The mass should read 0.0000 g.

- Open the door to place the container on the center of the scale.

- Close the door and wait for it to stabilize.

- Press ‘Tare’ to reset the mass to zero if you do not wish to measure the mass of the container.

- Remove the container and place the object you wish to weigh on the balance.

- Wait for 5 to 10 seconds before you see the reading. If the reading is unstable, the reason may be static electricity.

Tips for Improving Accuracy while using Analytical Balance

Accuracy is an important aspect of analytical balance, especially in industries such as compounding pharmaceuticals and researching. Analytical balance weighing accuracy is a measure of how close the actual weight is to the displayed weight. Here are some tips to help you attain analytical balance weighing accuracy:

- Consider the Location – You need to place the balance on a solid level surface to ensure minimum or no exposure to external factors that may affect the reading. The location should have minimal exposure to vibration, humidity, and temperature as these conditions often lead to inaccurate readings by either affecting the sample or balance.

If you’re not able to find a low-traffic area, look for a weighing scale that absorbs vibrations. Moreover, you can also shield the balance from external factors such as temperature and humidity to maintain the accuracy of readings. - Take into Account the Electrostatic Charge – This is particularly recommended when you are weighing dry and non-conductive samples that are likely to cause weighing errors. The electromagnetic field between the balance and the items can lead to distortion of the weight results. So, make sure you check for any electrostatic charge before the reading.

- Calibrate the Scale to Suit the Location – This is important because the effect of gravity on the sample varies with geographic locations. So, ensure that you calibrate or test your scale against an accurate device on a regular basis. It can be done on-site with the help of calibration weight or in an accredited calibration lab. Also, tare the balance before calibration since it should be level. All these measures are important to maintain the reliability of readings.

- Have Good Housekeeping Practices – Be sure to prevent the introduction of liquids in the weighing mechanism as this can tamper with the balance. Clean the balance area using cloths that are barely damp or dry. Avoid harsh solvents and only use a soft brush to remove any spilled solids.

- Avoid Contact with the Balance – Since vibrations can affect the readings, make sure that you don’t lean on the weighing table. In fact, it shouldn’t even be touched during the operation. So, avoid direct or indirect contact with the scale and shield the location effectively against any disturbance such as the movement of air.

Also, use tongs or gloves while handling the scale since fingerprints on the container can add mass to it and affect the readings. - Eliminate Possible Magnetic Effects – The magnetic field in the sample can generate force fields that have an effect on the weighing pan and chamber. To correct this, it is recommended that you perform demagnetization prior to weighing. You may also use a non-magnetic object to improve the distance between the weighing pan and the sample.

- Keep the Balance Clean – Dust, debris and other particles can add on to the mass and result in inaccurate readings. So, make sure that you clean your scale thoroughly before measuring anything. Use an appropriate solvent and a soft brush to do the same. Avoid using aggressive cleaning agents since they may damage your balance or scale.

In summary, analytical balance accuracy is crucial especially when you would like to know the precise weight of a particular substance. Therefore, you need to take into account a number of factors to ensure that no internal or external influence affects the outcome of the weight you are seeking to measure.

Quality Scales Unlimited offers a wide range of scales to meet specific business needs.To get a quote on analytical balances, contact Quality Scales Unlimited now.